Services

WE HAVE BEEN DESIGNING AND MANUFACTURING HIGH PERFORMANCE X-RAY TUBES SINCE 1960

The leading certifier of the quality of our work is our Customers. Acknowledging their implicit and explicit needs and satisfying them, is of prime importance in our eyes. The entire production process is continuously subjected to rigorous checks, which gives our Company the utmost reliability. Each component has to satisfy the quality level set by our Research & Development Department. Only after final testing, which simulates real operating conditions for X-ray tubes, can we proceed with delivery. Designing and manufacturing all our X-ray tubes are guaranteed by continuous application of C.E.I.’s procedures. Quality System – certified in accordance with the ISO 9001-2015 and ISO 13485-2016 standards, and CE certification.

Wide range of models that provide optimum performance.

A large number of models available for medical and industrial applications. Capacity to develop customised solutions in just a few weeks.

Quick, flexible delivery times

Due to our extensive automation and planning. Kanban and consignment stock options available.

Delivery of small batches

By request we also develop and manufacture small quantities of dedicated products.

Production

WE DESIGN AND MANUFACTURE HIGH PERFORMANCE X-RAY TUBES AT COMPETITIVE PRICES

- Total investment of € 2,000,000 over the last 5 years

- High degree of automation

- Optimisation of production costs and R&D

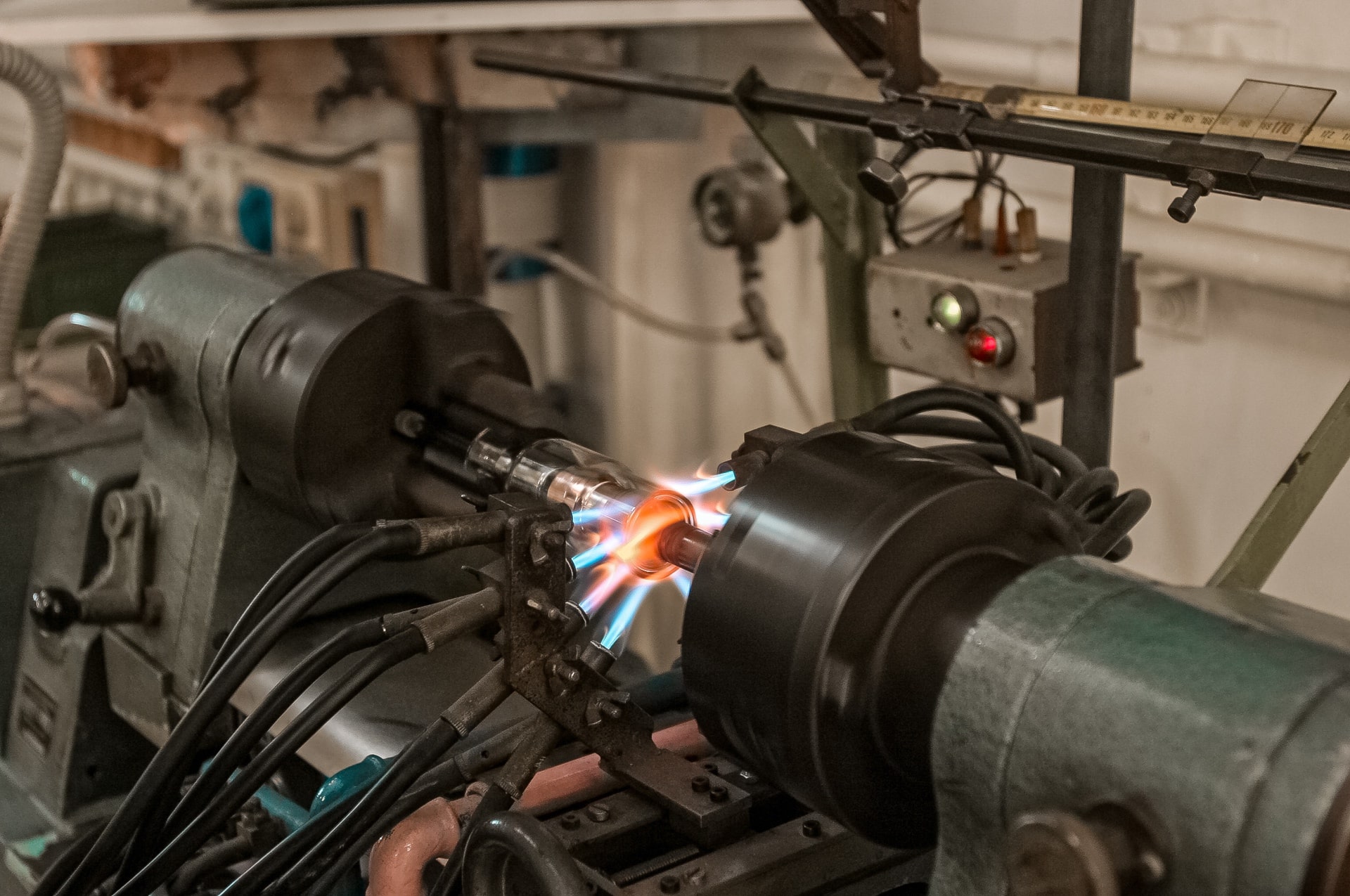

Glass blowing department

Great skill and experience in glass blowing goes hand-in-hand with a high degree of automation, to guarantee an excellent result every time.

Chemical department

The vacuum is, above all else, about cleanliness - automated cycles and eco-efficiency are the starting point for an optimum vacuum in the tube. Our Company is completely environment-friendly and does not produce any kind of emissions into the environment.

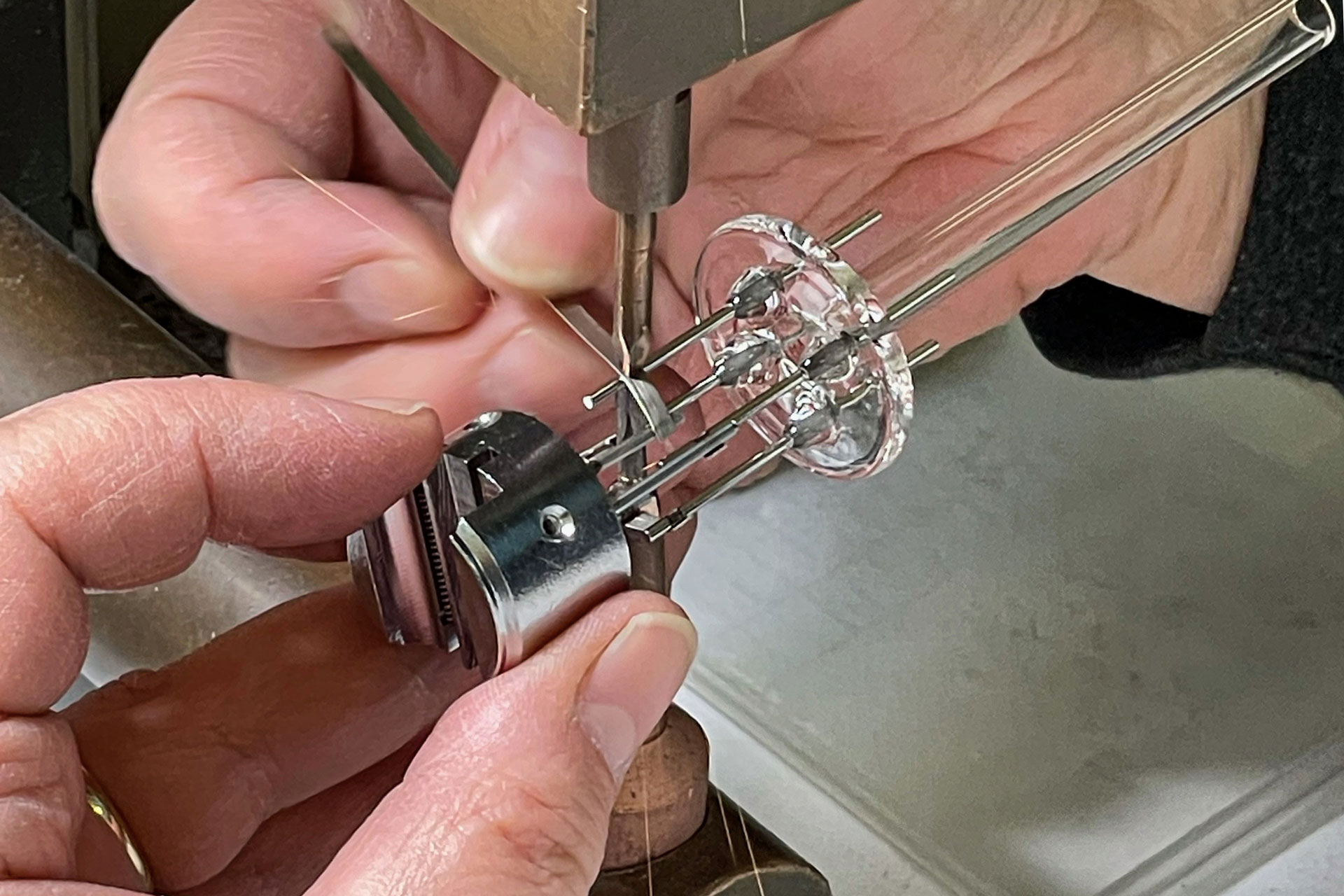

Cathode assembly

The high degree of specialisation of and low turnover in personnel ensure micro assembly that is always perfect.

High vacuum system

Our fully automated systems are able to work without the aid of personnel, thereby ensuring more efficient, high performance work processes.

Seasoning and Testing Department

Our fully automated, computer controlled machines ensure standardisation of results, by eliminating the human variable.